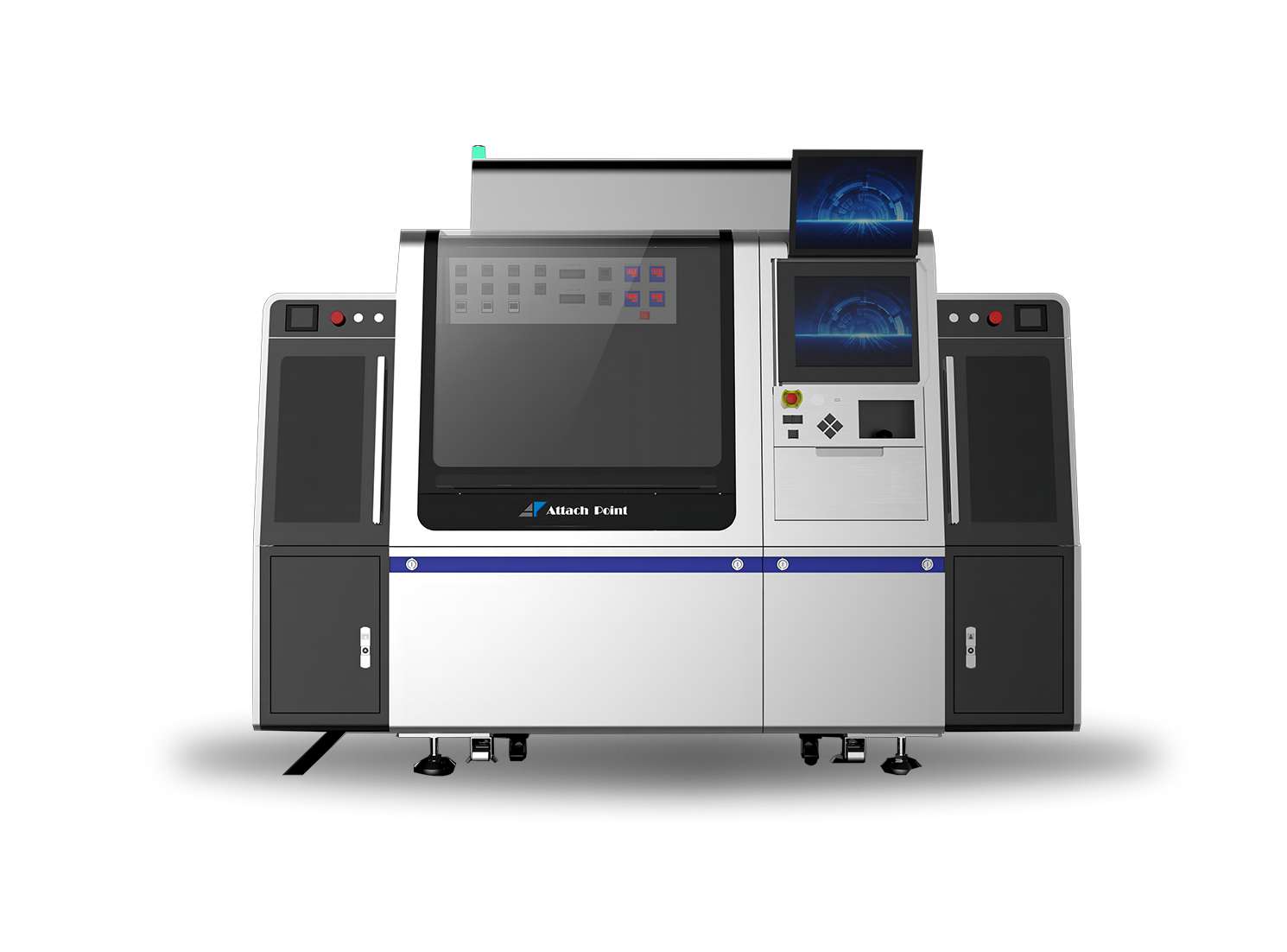

±10um Placement

Die Attach & Flip Chip

0 Defect for Automotive Application

High Cleanness Control Class 10

Dispensing Process Expertise

7+ Years Stable & Reliable HVM

+30% High Throughput

Continuously Mass Production

Fully Automated Load/Unload

Flexible Configurations

SECS/GEM Traceability

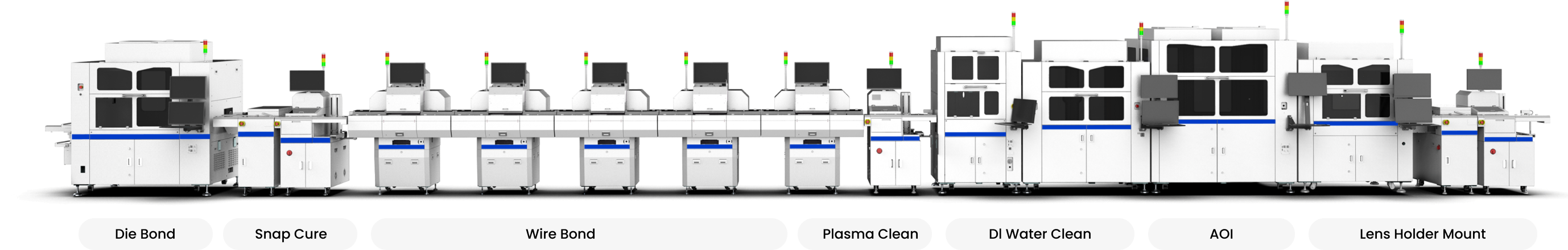

Turnkey Solution

| Item | Specifications |

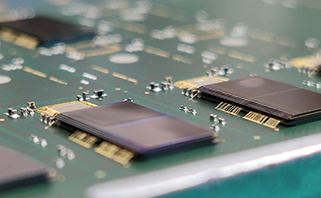

| End Market | Consumer/Automotive |

| Application | CCM/Automotive/IOT-COB, 3D-ToF, Fingerprint Sensor, IR Camera Module, VCM etc. |

| Material Handling | 4~12" Wafer, JEDEC Tray, Waffle Pack, etc. |

| Process | Dispensing, Jetting, Stamping, DAF |

| Die Placement | ±10um @3σ |

| UPH | Material Dependent |

| Footprint & Weight | Configuration Dependent |

Placement

Thin Die

Stacking

100

±5um Placement

Frictionless Precise Force Control

Vibration Suppression

25um Die Thickness

32-Hi Stacking

Key OSAT/IDM Running HVM

Leading UPH & OEE

Customized Functions

DAF & Epoxy Writing

Crack Free

Deep Learning Driven Vision

Support Industry 4.0

| Item | Specifications |

| Wafer | 6" ~ 12" |

| Die Size | 0.8 ~ 25mm |

| Die Thickness | ≥ 25um |

| Strip Length | 130 ~ 300mm |

| Strip Width | 55~100mm (Optional <55mm ) |

| Bond Force | 0.5 ~ 50N (70N optional) |

| Die Placement | ±5um @3σ |

| Item | Specifications |

| Process | DAF & Epoxy Dispensing |

| Cycle Time | Material Dependent |

| Heater Block | Max 250 ℃ (±5 ℃) |

| Die Stacking | YES |

| Packages | BGA/QFP/QFN |

| Footprint | 2292 x 1551 x 1900mm |

| Weight | 2450kg |

Placement

UPH

Flexibility

Footprint

±3um Placement

Qualified in Worldwide #1 Account

Advanced Packaging Solution

Optional High Force 50kg

Pre-Sintering SiC Die Attach

Modulization Design

Die Attach + Flip Chip, Stack Die, Multi Chip Mount

On The Fly Post Bond Inspection

Dual Mode (Speed/Precision)

Excellent Cleanliness Control

SECS/GEM Traceability

Support Industry 4.0

| Item | Specifications |

| Material Handling | 6~12" Wafer, JEDEC Tray, Feeder, Waffle Pack, Gel-Pak, etc. Support All Chip Trays, Substrates, Leadframes and Carriers |

| Die Size | 0.17 ~ 50mm |

| Die Thickness | ≥ 60um |

| Bond Force | 0.3 ~ 50N (Optional to 500N) |

| Die Placement | Down to ±3um@3σ (±5um/±7um Configuration Dependent) |

| Process | Die Attach, Flip Chip, Stack Die, Multi Chip Mount |

| Cycle Time | Material Dependent |

| Footprint | 1200 x 1650 x 2050mm |